Cause Analysis of Bolt Fracture

June 21,2022

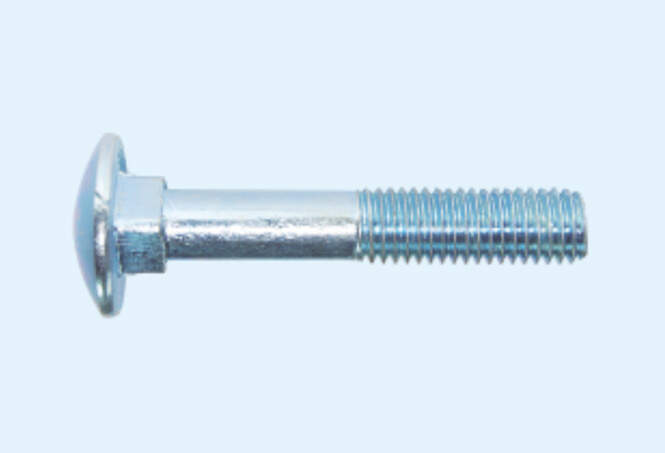

OEM Countersunk Head Square Neck Bolt,OEM Double Ended Stud Bolt,Special Carriage Bolt supplier

Generally, we analyze the bolt fracture from the following four aspects:

- Bolt quality

- Pre tightening torque of bolts

- Strength of bolts

- Fatigue strength of bolts

In fact, most of the bolts are broken due to looseness, and are damaged due to looseness.

Because the loosening and breaking of bolts are roughly the same as the fatigue fracture, finally, we can always find the cause from the fatigue strength. In fact, the fatigue strength is so large that we can't imagine that the fatigue strength of bolts can not be used in the process of use.

- The bolt fracture is not due to the tensile strength of the bolt

With one M20 × 80 grade 8.8 high-strength bolt, for example, weighs only 0.2kg, and its minimum tensile load is 20t, up to 100000 times its own weight. Generally, we only use it to fasten 20kg components, and only use one thousandth of its maximum capacity.

Even with the action of other forces in the equipment, it is impossible to exceed a thousand times the weight of the parts. Therefore, the tensile strength of threaded fasteners is sufficient and cannot be damaged due to the insufficient strength of bolts.

- The bolt fracture is not due to the fatigue strength of the bolt

The threaded fasteners can be loosened only 100 times in the transverse vibration loosening test, while they need to be repeatedly vibrated onemillion times in the fatigue strength test. In other words, the threaded fastener loosens when it is used with one ten thousandth of its fatigue strength. We only use one ten thousandth of its great capacity. Therefore, the looseness of the threaded fastener is not due to the fatigue strength of the bolt.

- The real cause of damage to threaded fasteners is looseness

After the screw fastener is loosened, a huge kinetic energy MV2 is generated, which directly acts on the fastener and equipment, resulting in the damage of the fastener. After the fasteners are damaged, the equipment cannot work under normal conditions, which further leads to equipment damage.

The thread of the fastener under axial force is damaged and the bolt is broken.

For fasteners subject to radial force, bolts are cut and bolt holes are made into ellipses.

- Select thread locking method with excellent locking effect

The root of the problem

Take the hydraulic hammer as an example. The weight of gt80 hydraulic hammer is 1.663t. Its side plate bolts are 7 sets of grade 10.9 M42 bolts. The tensile resistance of each bolt is 110 tons. The preload is calculated by taking half of the tensile resistance. The preload is as high as 300 to 400 tons. However, the bolts will also break. Now we are going to change them to M48 bolts. The fundamental reason is that the bolt locking cannot be solved.

When the bolt is broken, it is easy to draw the conclusion that the strength is not enough, so the method of increasing the strength grade of the bolt diameter is mostly adopted. This method can increase the pretightening force of bolts and the friction force. Of course, the anti loosening effect can also be improved. However, this method is actually a non professional method, with too much investment and too little profit.

Searching for a OEM Countersunk Head Square Neck Bolt,OEM Double Ended Stud Bolt,Special Carriage Bolt supplier from China, you can get high-quality products at a nice price.