Causes and Treatment of Stainless Steel Bolt Seizure

May 07,2022

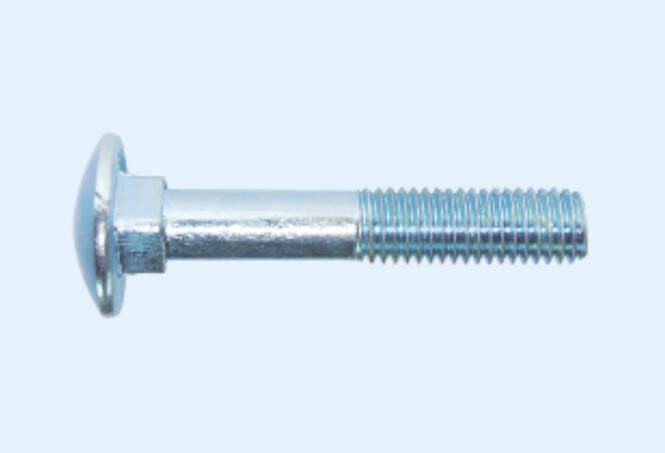

Fastenal Heavy Stainless Steel Holding Down Galvanized Hex Head Bolts Manufacturers

A threaded connection is a detachable connection, which is widely used. More than 60% of the parts of the equipment are connected through threads. When installing or overhauling equipment, we often spend a lot of time and effort on the elastic bolts.

In the process of fastening and dismantling Stainless Steel Eye Bolts, there is often a "bite" phenomenon, which often makes the thread in a dilemma, and finally leads to the destruction of the thread mating surface, and even the two mating parts are difficult to separate so that the whole assembly is scrapped. The parts had to be damaged and remade, delaying the construction period. It also causes economic losses.

Mechanism of seizing stainless steel bolts

It is a common problem for Stainless Steel Eye Bolts to bite during disassembly and assembly. The main reasons are as follows:

Stainless steel has its material characteristics.

Firstly, the stainless steel material itself has anti-corrosion performance, and a thin oxide layer will be generated on its surface after being damaged to prevent further corrosion. When the Stainless Steel Eye Bolt is locked, the pressure and friction generated by the mutual movement between the screw teeth will destroy and erase the oxide film on the screw teeth. [Fastenal Heavy Hex Bolt]The instantaneous high temperature generated by friction is converted into high-density heat energy, which will aggravate the damage speed of oxidation film, block or shear between metal threads, and then adhesion occurs.

With repeated disassembly and assembly, this phenomenon will continue to occur. Finally, the Stainless Steel Eye Bolts are completely locked and can no longer be removed. Usually, a series of actions such as blocking, shearing, sticking, and locking occurs in just a few seconds.

Secondly, stainless steel has good ductility, and the steel scraps produced during use stick to the tooth shape of the nut. [Stainless Steel Holding Down Bolts]The friction force is increased. With the gradual increase of the tightening force to overcome the friction force, this biting phenomenon is further exacerbated. In particular, the probability of bite death between similar stainless steel fasteners is much higher than other types of bite death.

External causes of stainless steel bite

Including rough embossing or adhesion of foreign matters. If there are metal chips sandwiched between the teeth, it will often lead to locking; Wrong selection of tools, too much force, or too fast tightening of electric tools; [Galvanized Hex Head Bolt Manufacturers]The angle of the force application direction is wrong, the nut is not perpendicular to the screw, and it is not screwed along the axis when tightening.

Stainless steel bolt seizure solution

Surface coating.

Surface coating can greatly reduce the friction coefficient and effectively reduce the biting probability of Stainless Steel Eye Bolts. Experience shows that reducing the mutual matching friction of stainless steel thread pairs can better avoid the seizing problem. Based on this, the design principle of the anti-seizing material formula is put forward: reducing the friction and lubrication effect is good, preventing the direct friction of matching thread pairs, and improving the matching surface between threads.

In addition, the cleanliness of coating and connecting materials should be considered as much as possible. In addition, the adaptability of coating materials to high-temperature working conditions should be considered. Coating materials commonly used in industry include butter, molybdenum disulfide, etc.

Thermal control.

Heat is an important factor in the seizure of Stainless Steel Eye Bolts. Friction in the assembly process leads to heat accumulation, and the heat increases with the acceleration of speed. Reducing the assembly speed can also reduce the risk of seizures. Torque wrench or socket wrench shall be selected as far as possible, and an adjustable wrench or pneumatic or electric wrench shall be avoided. Electric wrenches often cause people to spin too fast, and the temperature rises sharply, resulting in death.

Material selection of different brands.

According to the experiment, once the stainless steel material of the same brand is rotated, it can be bitten to death, so try to use different types of stainless steel materials. The matched stainless steel materials are the same, which is easier to cause bite than the stainless steel of different materials. When similar materials need to be selected due to design requirements, different hardness values shall be specified.

Thread surface quality.

The thread lines must be kept clean. Rough lines or foreign matters (such as solder joints and other metal chips mixed between the lines) will increase friction and lead to locking.

Stop the nut.

Stop nut is an effective lubrication method. Its process principle is to use German gleitm0615 transparent dry film lubricant (water wax) to carry out a special process treatment on 304 nuts. After treatment, the torque can be reduced, the tightening force can be increased, and the wear resistance of the nut can be improved.

Variable thread is adopted.

There is a wedge-shaped inclined plane at the tooth bottom of the female thread. When the bolts and nuts are tightened with each other, the tooth tip of the bolt is firmly against the wedge-shaped inclined plane of the variable thread, resulting in a great locking force. Moreover, the thread contact area is small, and the metal fusion degree will be much smaller, so it is not easy to bite.

Fastenal Heavy Stainless Steel Holding Down Galvanized Hex Head Bolts Manufacturers, you can get high-quality Hook Bolt Anchors at a nice price.