Everything You should Know about Anchor Bolt

April 29,2022

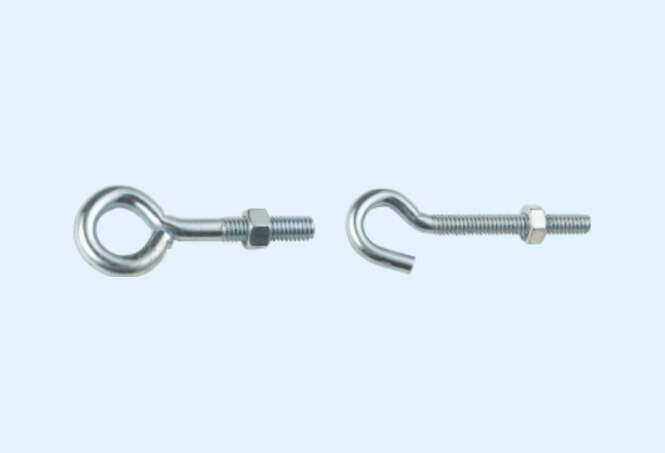

Anchor bolts refer to bolt members with right-angle hooks at the lower end or L-shaped and U-shaped bolts. The Sleeve Anchor Bolt has the function of increasing anchorage, increasing the bearing load of the equipment, and can play a good stabilizing effect even in motion and earthquake. Therefore, the installation of anchor bolts plays a very obvious role in ensuring the safe transportation of goods and prolonging the service life of valuables.

In addition, to ensure the quality of bolts embedded in the foundation tower, great attention should be paid to the selection and installation process of anchor bolts. According to its different application scope and technical essentials, the quality of installation construction should be strictly controlled from the aspects of construction hole size, embedded depth of concrete, formwork removal, and acceptance.

Classification of common anchor bolts

-

Movable anchor bolt.

The movable anchor bolt, also known as the long anchor bolt, is cast from Q235 steel. Its obvious feature is that it is easy to disassemble. Therefore, it is suitable for installation on heavy machinery and equipment with strong vibration and impact.

-

Fixed anchor bolt.

In contrast to the movable bolt, the fixed bolt is called a short leg bolt. One end of this bolt is placed in concrete, so it has very good stability. It is suitable for installation on mechanical equipment with weak vibration and impact force during operation.

-

Grip-type anchor bolt.

The ground holding anchor bolt is also called the bonding anchor bolt, which has been widely used in Construction Engineering in recent years. Its installation method is similar to the expansion Sleeve Anchor Bolt, but it is necessary to remove the sundries on the inner wall of the hole and keep the inner wall dry when implementing the ground bonding process.

-

Expansion anchor bolt.

Expansion anchor type anchor bolts are widely used. In addition to the commonly used static equipment, they can also be installed on auxiliary equipment. When installing the expansion anchor bolt, pay attention to setting the installation mechanical pressure above 10MPa. If the pressure is too small, it is easy to cause the bolt to slip or fall off. At the same time, pay attention to the strength when using the drill bit to avoid damaging the buried pipe with excessive force. After the bolts are driven into the foundation, carefully observe whether there are cracks around. Once cracks are found, try your best to repair them to prevent the bolts from loosening.

Installation steps of anchor bolts

-

Instruments and equipment required for installation and relevant requirements.

In the process of Sleeve Anchor Bolt construction and installation, the most critical link is instrument measurement control, and a large number of instruments and equipment are involved in the installation process, and there are high requirements for their operation. Therefore, accurately controlling instruments and skillfully operating theodolite, level, and other measuring tools are the skills that installers must have before taking up their posts. The engineering quality of anchor bolts is directly related to the operation and safety of industrial equipment. During installation, we should try our best to avoid data errors and make the installation more accurate. In this way, the operator needs to fix the support, fine-tune the bolts, and do a good job in the preliminary commissioning to ensure the subsequent installation quality.

-

Fixing of bolts.

The fixing of anchor bolts is the first step of installation. First, check the anchor bolt, remove the dirt and oil stain on the surface of the galvanized layer, apply lubricating oil to the thread, and check whether the bolt matches the nut. In the process of fixing, be careful not to mix dust and sundries into the bolt hole, otherwise, the sundries will be brought into the grouting process. Then the bolts need to be grouted through pressure electromagnetic sensing. At this time, it should be noted that the hook at the lower end should keep a distance of two fingers wide from the bottom to prevent the gap from being too small to be filled during grouting. If the equipment is installed in the basement or on the concrete floor slab on the foundation, the L Shaped Anchor Bolts hook shall be hooked on the reinforcement. If the equipment has no reinforcement, use round steel to cross through the hook.

-

Determine the elevation of the bolt mounting bracket.

The deviation is common in the installation of industrial equipment. The allowable range of deviation is different for different construction projects, and the installation error of L Shaped Anchor Bolts is strictly controlled, which needs special attention in the installation process. When measuring the elevation, the four corners of the top surface of each steel frame shall be measured separately. If the measured elevation is found to be lower than the design elevation, it is necessary to pad the steel sheet or iron sheet to reduce the error. After the erection elevation meets the requirements, the lower part of the steel frame shall be welded and fixed with the embedded parts on the bottom base platform. After welding, pay attention to cleaning and check all matters in the technical disclosure text with relevant personnel.

Summary

To sum up, in the mechanical equipment installation project, the selection of L Shaped Anchor Bolts and installation quality are closely related to the stability and safety of engineering equipment. In the actual construction process, the preliminary preparation shall be made in strict accordance with relevant regulations. Once any deviation is found, it must be corrected in time, and then the information shall be checked according to the instructions of equipment configuration or technical disclosure scheme. Only in this way can the installation quality of the whole equipment be guaranteed.

If you want to Buy Heavy Duty Anchor Spikes, welcome to contact us!