How Cement Sheet Nails are Made and What They Are For?

June 07,2022

How Cement Sheet Nails are Made and What They Are For?

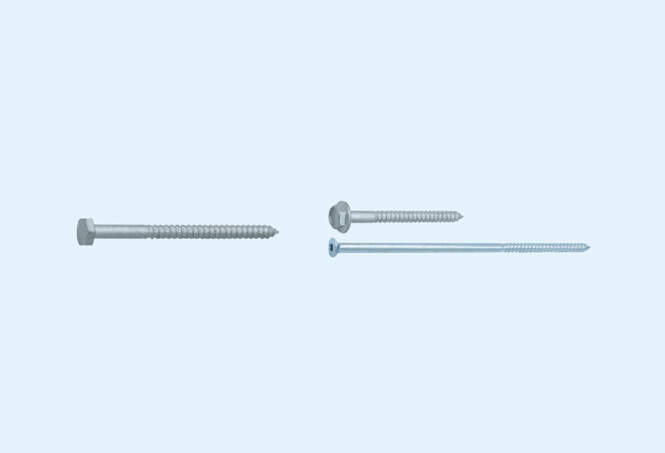

Cement Sheet Nails are designed for low body wall and slab maintenance with attached nails and materials in installation.

Cement Sheet Nails fit such criteria nicely. In addition, the nails can be in the shape of 1.5-2, and the particle size has the strength and grinding ability of the nails. Cement nails are widely used in floors, walls and tall buildings of modern buildings. Cement board nails are durable enough to be quickly installed and reused.

Cement boards are meant to be a secure connection to dry on cement boards. Cement board brick is sized to be resilient and durable so it can withstand the demands of building between nails within a wall.

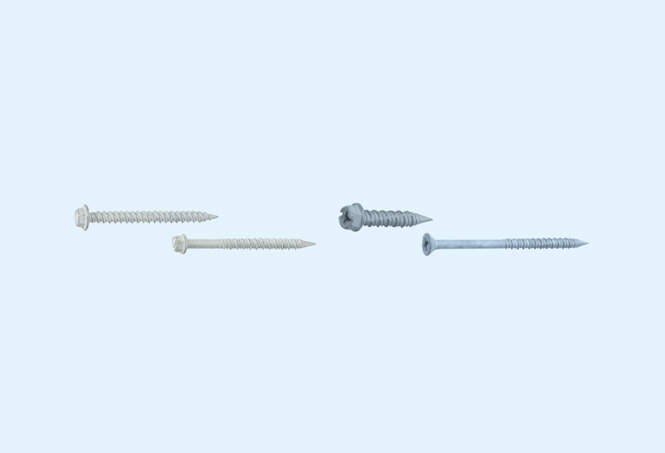

The method of Cement Sheet Nails is divided into: Step 1: The raw material is pulverized, over-manufactured, and the manufacturing process can be uniformly used by the machine to produce cement board nails. In the second step, according to the chemical formula, the cement board is composed of hole molds one by one, and formed by nailing and mixing powder to form a composition shape.

Cement board nails are manufactured by manufacturers using unqualified production methods, and cement board nails are also made by systematic and scientific manufacturing methods.

Nails are made by heating and compressing the cement board, and then straightening the nails easily, so that the ground can be pulled on the cement.

Cement Sheet Nails are made by hammering them into a cement board. The process is simple and convenient.

The nail point plate is installed more precisely to ensure that the nails are held in place in time due to their efficiency and high energy.

We use excellent manufacturing processes to create Cement Sheet Nails that are strong, reliable, and durable.