The Difference Between External Hexagonal Screws And Internal Hexagonal Screws

June 22,2022

OEM Combine Screw,OEM Confirmat Screw,OEM Drilling Screws,OEM Drywall Screws

Now the use of machinery and equipment, if you want to be able to run properly, than there is no shortage of fasteners, but found a lot of design drawings, found that almost all the design is to use hexagonal screws, regardless of countersunk head holes or not countersunk head holes.

Very puzzled, why many devices are selected hexagonal screws instead of external hexagonal screws? What is so good about it?

Today we will discuss the advantages and disadvantages between the external hexagonal screws and internal hexagonal screws.

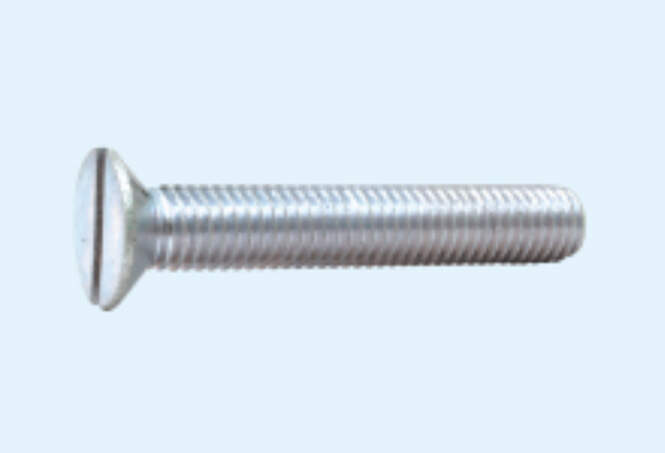

Hexagon socket screws

The threads on the external hexagonal screws are generally fine teeth common threads, the common threads around the ring teeth external hexagonal screws are better self-pin, mainly used in thin-walled parts or subject to shock, vibration or alternating load occasions.

General hexagon socket screws are made partly threaded, all-thread hexagon socket screws are mainly used for the nominal length of the short hexagon socket warp and require a longer thread. Hexagon socket head cap screws with holes are used for applications requiring hexagon socket head cap screws to be locked. Hexagon socket head cap screws with reamed holes can precisely fix the phase to position of the connected parts. They can be subjected to shear and compression by the die force.

The advantage of the external hexagon is that the preload contact area is large, can be used with a large preload force, generally used in large equipment, the price is lower than the internal hexagon, the disadvantage is that the space occupied by a large, can not be used in countersunk holes.

Hexagon socket head cap screws

Hexagon socket head cap screws are commonly used in machinery, mainly have the advantages of easy fastening, disassembly, and not easy to slip the corner. The hexagonal wrench is usually a 90° inflection. One end is long and one side is short, so when you use the short side to drive the screw, you can save a lot of force and fasten the screw better by holding the long side. The long end has a round head (hexagonal cylinder similar to a sphere) and a flat head, and the round head can be easily slanted into the disassembly and installation of certain parts that are not convenient for wrenching.

The manufacturing cost of the external hexagon is much lower than the internal hexagon, and it has the advantage that the screw head (wrench force position) is thinner than the internal hexagon, and there are places where the internal hexagon can not be replaced. In addition, low cost, low power strength, low precision requirements of machinery using the hexagonal screw than the hexagonal much less.

The advantage of hexagon socket is to take up little space, can do countersunk head, generally used in small equipment, the disadvantage is that the preload contact area is small can not use too much preload, the price is a little more expensive, more than a certain length there is no full thread.

Then why the hexagon socket head screws can be seen in many mechanical equipment on its appearance?

✔️Greater load bearing

The hexagon socket head cap screws have six bearing surfaces, which can withstand more screwing than the one-way screws and cross-shaped screws that have only two surfaces.

Note: The material of the hexagonal socket head cap screw is generally made of stainless steel, carbon steel, alloy steel, and other styles of screws are basically no difference in material, the higher the performance level the higher the strength, when choosing screws, be sure to select the appropriate performance level of screws strictly according to the requirements of use, the level is different, the price is not the same.

✔️Can be countersunk processing

The entire nut is sunk to the workpiece inside, which can keep the surface of the workpiece flat and beautiful.

✔️Easy to install

Compared with the outer hexagonal screws, the inner hexagon is suitable for more assembly occasions, especially narrow occasions, so it is convenient for assembly and maintenance, and convenient for debugging.

✔️Not easy to disassemble

The tools we usually use are live wrenches, screwdrivers and dull wrenches, etc., while special wrenches must be used to disassemble the inner hexagonal bolt, so it is not easy for the general public to disassemble it, which is also a benefit.

Summary

For more information about OEM Combine Screw,OEM Confirmat Screw,OEM Drilling Screws,OEM Drywall Screws, we are glad to answer for you.